Understanding power scaling inserts and tips

Model T cars, popularized by Ford, allowed Americans to participate in a technology wave that changed the way middle-class Americans traveled. Motorized transportation, in all its forms, is a given in today’s world.

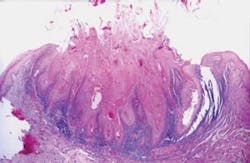

Scaling with a slim universal tip

It’s unlikely that Irene Newman or Alfred Fones could have envisioned removing stain, calculus, or biofilm with a power-driven scaler.1,2 Hand scalers and porte polishers were the standard of care in their day. Just 50 years after the birth of the profession, a new device called a Cavitron created a technology wave that added a new dimension to deposit removal.

Ultrasonic scalers come in two platforms: magnetostrictive and piezoelectric. These two options are similar to choosing between a vehicle with a combustion engine or one powered by diesel. Both types of engines can power a car, but their internal mechanisms are different. Activated piezo tips move in a linear fashion, like erasing a chalkboard, while magnetostrictive insert tips have an elliptical figure-eight pathway.3

If a power-driven scaler is analogous to a car engine, tips or inserts are the scaler equivalent to an automobile’s wheels and tires. Every type of vehicle has exact tire and wheel requirements. It takes a very different set of tires to successfully maneuver dirt back roads than a precision racetrack. Road conditions also complicate the situation. Off-road terrains, icy-slick freeways, and rain-drenched asphalt neighborhood streets require more diligence than driving on bone-dry concrete.

In order to take full advantage of today’s power scalers, it is important to understand the wide variety of tip options and their unique clinical applications. Years ago, power scalers were generally used for heavy debridement, and the majority of instrumentation was done by hand. With the development of machines that can operate at low power levels using a wide range of tip and insert designs, more and more clinicians now use power scalers as their primary instrument of choice.

Installing a piezo tip with a torque-limiting wrench

Today’s ultrasonic landscape is heavily populated with information from companies that have both units, tips, and inserts as well as companies that sell after-market replacement tips and inserts. Internet sites are a rich source of information, and many companies such as Hu-Friedy and Satelec have valuable videos that demonstrate various scaling techniques with different tip designs.

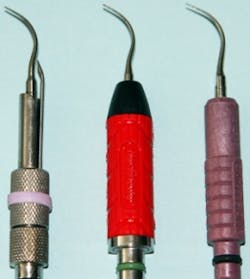

Wide variety of tip designs available for piezo electric ultrasonic dental scalers

Scaling tips used in magnetostrictive units are called inserts, a term that describes how the device fits into the handpiece. Magnetostrictive inserts are made with a series of nickel alloy strips stacked one on top of another, attached to a scaling tip via a connecting body called a transducer. Magnetostrictive inserts come in either 30K or 25K configurations. Most automatically tuned machines use the shorter 30K inserts, while a few units will accept either a 25K or 30K insert.3

Right and left tip configurations

For piezo scalers, the scaler portion is referred to as a tip. Piezo tips screw directly into the handpiece, which houses the crystal that creates tip vibrations. Piezo units use two different thread patterns to screw the tip into the handpiece. S-threaded tips work with Satelec scalers and compatible units. An E-thread works with EMS piezo scalers and units that accept that thread pattern. The tip is initially screwed onto the handpiece and a small wrench is used to ensure the tip is secure. Torque-limiting wrenches ensure that the tip is not over-tightened.

In the early years, magnetostrictive ultrasonic insert tips were bulky and robust. Two shapes were popular for removing heavy supragingival deposits and stain: a thick cylindrical universal insert tip and the flat, wide beavertail. Forty years ago, Tampa-area periodontist Dr. Tom Holbrook started reshaping and refining magnetostrictive insert tips, creating the first universal slim profile, a design now available from all magnetostrictive manufacturers. Ultrasonic Services Inc., Dentsply, and Hu-Friedy each offer an ultra-thin precision universal insert that is the diameter of the thinnest periodontal probe. As a result, today’s clinicians can choose from a wide range of commercially available magnetostrictive designs that range from robust thick to micro-thin inserts that are a fraction of the diameter of the first ultrasonic inserts.

Robust tips are designed to work with a full range of power levels in either magnetostrictive or piezo electric units; however, they are generally used to remove gross deposits quickly,4,5 followed by more slender tips at lower power settings to complete the task.5,6 Parkell’s Burnett Power tip is an example of a robust tip specifically designed to remove heavy stain as well as tenacious calculus. Slim and micro-thin designs should be used on low power since they are not designed to withstand the forces created on high power settings. Thinner inserts are the instrument of choice for removing light deposits,7 instrumenting tight areas, or simply disrupting biofilm. Used at very low power levels, micro-thin tips dramatically reduce or even eliminate the need for pain-controlling anesthesia. Tips that are the diameter of a periodontal probe or an 11/12 explorer improve tactile sensitivity, a benefit when scaling subgingivally.8

Comparing the diameter of ultra-slim insert tips to 6/7 anterior scaler and 11/12 explorer

Right and left tip designs, available for both magnetostrictive and piezo scalers, improve access to complex root anatomy, furcations, around malpositioned teeth, and fixed orthodontic or periodontal appliances. While right and left configurations are commonly considered posterior instruments, the convex surface of either tip is an ideal solution for scaling lower anterior teeth that have a lingual tilt.

Heavy debridement tips: Universal 10, Burnett Power tip, Triple Bent, P-10

The triple bend design, a dramatic departure from cylinder-shaped magnetostrictive inserts, is a bladed insert, designed with beveled edges that facilitate the removal of heavy stain and deposits. Dentsply recently introduced a more petite triple bend insert for subgingival use. A growing number of piezo tips are now available with beveled edges, a design that pairs well with piezo’s linear tip movement. There are also piezo tips shaped like conventional curettes without a sharp cutting edge.

Magnetostrictive inserts move in an elliptical or orbital path, with the lateral surfaces producing the least vibration and the highest level of patient comfort. At the same power setting, the convex and concave surfaces produce stronger vibrations than those created on the lateral surface of a magnetostrictive tip. Adapting the lateral surface of a piezo scaling tip to the tooth results in the smoothest feel on the tooth surface.

The fluid irrigant in ultrasonic scaling is required to create cavitation, an essential component in biofilm disruption and deposit removal. Water is the most common fluid irrigant. Some use antimicrobial medicaments or fluoride rinses as the irrigant but chemicals like these can shorten the life of a power scaler. The fluid also washes away debris, acts as a lubricant between the tip and the tooth, and cools the vibrating magnetostrictive tip. It is important to adjust the fluid flow for each individual insert. Robust tips require more

Autoclavable cassettes provide safe storage for ultrasonic insert tips

water than thin tips.5 Less water is required when using a piezo or a manually tuned magnetostrictive unit.

A number of different grip and water-flow designs are available for magnetostrictive inserts. All-metal inserts and some resin-hubbed inserts have thin water conduits that deliver the cooling irrigant directly to the back of the tip. Water flow on other magnetostrictive inserts and all piezo tips comes from a small hole at the base of the tip, allowing the irrigant to flow directly to the tip. Some inserts have a metal body covered with medical-grade silicone or a padded grip, adding to overall comfort. Clinicians who use manually tuned units generally prefer all-metal inserts.

Hu-Friedy has a line of inserts that have a swivel fingertip grip, allowing the user to maintain a more neutral wrist position when adapting the tip to the tooth surface. Illumination is also available in piezo technology, but the light is in the handpiece. Satelec has both periodontal and biofilm straight debridement piezo tips with marks corresponding to a 3-6-9-12 probe laser-etched on the tip surface.

Implants and burnished calculus create unique clinical situations. Studies indicate that metal tips can scratch titanium implants, creating rough surfaces conducive to biofilm development.9 Plastic-covered tips or sleeves are available for both piezo and magnetostrictive tips. In addition, Satelec has carbon composite tips, a material that is kind to implants and cosmetic restorative materials. Burnished calculus can be removed with a diamond-coated ultrasonic tip, but it is particularly important to use a low power setting and a feather-light touch to prevent damaging tooth structure.7 NSK, Hu-Friedy, and Satelec each have ultra-thin diamond-coated piezo tips that are designed for removing burnished deposits. The Dentsply Diamondcoat 30K insert is recommended for debridement during flap surgery only.

While ultrasonic inserts and tips are built to withstand the rigors of scaling, there are protocols that will help ensure optimal scaling outcomes. Many inserts and tips come with color-coding that identifies the type of insert as well as the appropriate power range, which helps avoid premature breakage. Colored instrument rings, installed on the insert grip, are the perfect answer to quickly differentiate all-metal inserts.

Three brands of ultra-slim tips: Ultrasonic Services Inc. E+ tip, HuFriedy XT tip, Dentsply Thinsert

Standard autoclave bags provide a sterile environment; however, there is limited protection if the bags are dropped or mishandled. Autoclavable instrument cassettes, made from either metal or plastic, are ideal storage units for magnetostrictive inserts, providing a secure environment for the stack and tip. Some piezo tips are housed in a protective color-coded carrier that also doubles as a tightening wrench, a valuable device that reduces the risk of losing small tips and helps identify a class of tips at a glance.

Ultrasonic scaler inserts with padded grips

Ultrasonic inserts and tips can be safely cleaned in an ultrasonic bath using a mild solution. Surface debris can also be removed with a soft brush and mild detergent. Avoid using strong disinfectants or bleach solutions. Rinse inserts thoroughly and autoclave in a steam sterilizer. Dry heat sterilization will damage magnetostrictive O-rings.

Worn-out, broken, or bent ultrasonic scaling tips can’t be expected to effectively remove stain or calculus or disrupt biofilm.10 Tip wear is subtle, occurring over a period of time. A wear guide is a useful, impartial tool. Place your existing tip over the corresponding image to determine if it is time to replace a tip or insert. It is estimated that a 2 mm reduction in tip length reduces scaling efficiency by 50%. The Scorpion piezo tips, available from Paradise Dental Technologies, have a layer of gold-colored titanium nitride at the terminal end, providing visual proof that the tip is not worn out.

Both the MadUltrasonics and the Tony Riso Company have services for retipping or rebuilding some types of magnetostrictive inserts. Some clinicians find these services helpful in extending the life of their inserts, while others prefer to discard worn inserts.

Just like tires, all inserts are not created equal. Unless one is a tire expert, it is impossible to evaluate performance with a quick glance. Evaluating an ultrasonic insert without using it in your machine is limited as well. Metal alloys, insert components, and manufacturing specifications can vary widely.11-13 Wear resistance can also differ. A university study found that American Eagle’s XP technology, a specially filtered titanium nitride/stainless steel alloy was more durable when compared to traditional stainless steel.14

When evaluating products by different manufacturers, one insert’s performance can differ from another even if the design is the same.11-13 The true test is how well an insert performs in your machine. Is the insert comfortable in your hand? Are the vibrations smooth or rough? Does the insert remove deposits when activated at the appropriate power level? Is the patient comfortable?

Today’s dental hygienist would shudder at the thought of not having a power scaler of some sort. In fact, a growing number of academic institutions require students to purchase their own ultrasonic inserts. Complete ultrasonic units are part of one’s instrument kit at some schools. It is also becoming increasingly common for clinicians to own their own equipment.

Whether one drives a magnetostrictive or a piezo electric is not the debate, but understanding what to expect from an insert is a hallmark of a skilled ultrasonic clinician. Ongoing research and clinical observations demonstrate that careful ultrasonic instrumentation provides efficient and thorough biofilm disruption and deposit removal,1,2 with significantly less musculoskeletal stress for the clinician.15

References

1. Ramage G, Culshaw S, Jones B, Williams C. Are we any closer to beating the biofilm: novel methods of biofilm control. Curr Opin Infect Dis. Dec. 2010; 23(6):560-566.

2. Müller P, Guggenheim B, et al. Potential of shock waves to remove calculus and biofilm. Clin Oral Investig. Dec. 2011; 15(6):959-65. Epub 2010 Sep 7.

3. Guignon AN, Henson H. Essentials of Dental Hygiene: Clinical Skills. Power Driven Scaling. New Jersey: Prentice Hall, 2005; 83-114.

4. Jepsen S, Ayna M, et al. Significant influence of scaler tip design on root substance loss resulting from ultrasonic scaling: a laserprofilometric in vitro study. J Clin Periodontol. Nov. 2004; 31(11):1003-1006.

5. Lea SC, Landini G, Walmsley AD. Vibration characteristics of ultrasonic scalers assessed with scanning laser vibrometry. J Dent. May 2002; 30(4):147-151.

6. Lea SC, Felver B, Landini G, Walmsley AD. Ultrasonic scaler oscillations and tooth-surface defects. J Dent Res. Mar. 2009; 88(3):229-234.

7. Lampe Bless K, Sener B, et al. Cleaning ability and induced dentin loss of a magnetostrictive ultrasonic instrument at different power settings. Clin Oral Investig. Apr. 2011; 15(2):241-248.

8. Ryan DL, Darby M, Bauman D, et al. Effects of ultrasonic scaling and hand-activated scaling on tactile sensitivity in dental hygiene students. J Dent Hyg. Winter 2005; 79(1):9.

9. Baek SH, Shon WJ, Bae KS, et al. Evaluation of the safety and efficiency of novel metallic ultrasonic scaler tip on titanium surfaces. Clin Oral Implants Res. Sept. 30, 2011.

10. Lea SC, Landini G, Walmsley AD. The effect of wear on ultrasonic scaler tip displacement amplitude. J Clin Periodontol. Jan. 2006; 33(1):37-41.

11. Lea SC, Landini G, Walmsley AD. Ultrasonic scaler tip performance under various load conditions. J Clin Periodontol. Oct. 2003; 30(10):876-881.

12. Trenter SC, Landini G, Walmsley AD. Effect of loading on the vibration characteristics of thin magnetostrictive ultrasonic scaler inserts. J Periodontol. Sept. 2003; 74(9):1308-1315.

13. Lea SC, Landini G, Walmsley AD. Displacement amplitude of ultrasonic scaler inserts. J Clin Periodontol. Jun. 2003; 30(6):505-510.

14. Gorokhovsky V, Heckerman B, Watson P, et al. The effect of multilayer filtered arc coatings on mechanical properties, corrosion resistance, and performance of periodontal dental instruments. U of Toronto. Unpublished.

15. Bains VK, Mohan R, Bains R. Application of ultrasound in periodontics: Part II. J Indian Soc Periodontol. Sept. 2008; 12(3):55-61.

Past RDH Issues

About the Author

Anne Nugent Guignon, MPH, RDH, CSP

ANNE NUGENT GUIGNON, MPH, RDH, CSP, has received numerous accolades over four decades for mentoring, research, and guiding her profession. As an international speaker and prolific author, Guignon focuses is on the oral microbiome, erosion, hypersensitivity, salivary dysfunction, ergonomics, and employee law issues. She may be contacted at [email protected].